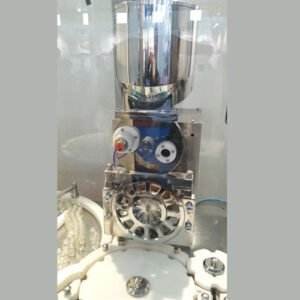

Injectable Powder Filling With Rubber Stoppering Machine

An Injectable Dry Powder Filling Machine is an efficient machine that can fill up dry powder into vials. Injectable Powder Filling with Rubber Stoppering Machine is a highly efficient machine that facilitates the injection of powder in vials, bottles and other containers. This vial filler also seals the top of the vial once it’s filled with the rubber stopper. This machine is designed with a high degree of efficiency in mind. It can be used to fill the vials and Plastic, HDPE Bottles with dry powder. This machine is designed for safer operation in sterile environments and for use under laminar flow protection. Stoppering and filling units are very close to each other, so there’s no risk of contamination. Machpack machines are one of the leading Injectable Dry Powder Filling Machine manufacturers. This maximum precision Injectable Dry Powder Filling Machines is ideal for running a production line for a long time without failure.

Features of Injectable Powder Filling With Rubber Stoppering Machine:

- Heavy duty base with robust construction off S.S. matt finished body

- Suitable for 50 Mg to 1.5 gms with the help of change part

- The minimal distance between filling and stoppering units reduces the risk of contamination

- The machines are designed for operation in a sterile area and for use under laminar flow protection

- Multiple Filling range with arrangement of different syringes and change parts

- Vials will have complete grip throughout the process for proper fill and no spillage

- No vial No fill arrangement

- No vial No stopper arrangement

- Easy and accurate adjustments of fill desired quantity with the help of change parts

We also offer Multihead Capping Machine. To know more click here.

You must be logged in to post a review.

Technical Details

| Number Of Filling Head | Single dose / Double dose / Triple dose / Four dose |

| Number of Inner Head | 1 |

| Number of Sealing Head | NA |

| Number of Applicator | NA |

| Production / Rate | Up to 120 Fills/Min. for Single dose / Up to 60 Fills/Min. for Double dose / Up to 40 Fills/Min. for Triple dose / Up to 30 Fills/Min. for Four dose Bottle/min (Fill Range Depends Upon Vial Opening and bulk density of powder) |

| Fill Size | 50 gm to 1000 gm (with the help of change parts) / 1.5 grms to 6 grms. (with the help of change parts) / 1.5 grms to 6 grms. (with the help of change parts) / 1.5 grms to 6 grms. (with the help of change parts) |

| Type of Product | Vials, Plastic, HDPE Bottles |

| Type of Filling Material | Dry Powder Syrup |

| Type of Seal | Rubber Stopper |

| Type of Label | NA |

| Label Specification | NA |

| Material Contact Part | SS 316 |

| Material Non-Contact Part | SS 304, SS Cladded MS Body Plate |

| Type of Technology | Linear, Controller Based / PLC Based |

Reviews

There are no reviews yet.