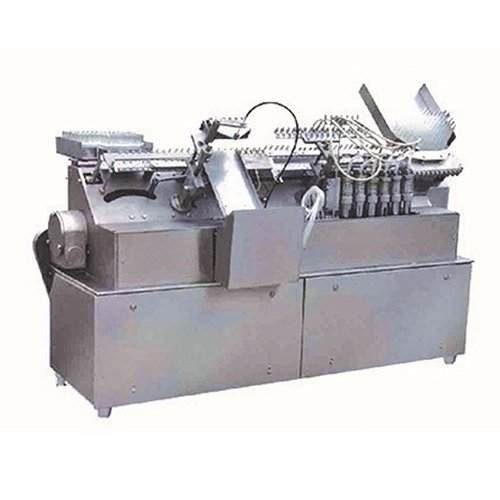

Ampoule Filling And Sealing Machine

Filling Range: 1 ml to 100 ml (No Need of Change Parts)

Output: 30 to 80 per minute. (Depending upon Liquid and Ampoule)

Applicable Industry : Pharmaceutical, Ayurvedic, Nutraceuticals, Cosmetic and relevant

Suitable for pharmaceutical products

An Automatic Ampoule Filling and Sealing Machine is an automation device that can speed up the ampoule filling and sealing process. It is a machine designed to automatically fill and seal ampoules with medicines, vaccines, chemical powders or other liquids. Ampoule Filling and Sealing Machines are one of the most important pieces of machinery in the pharmaceutical industry for sealing vials, syringes or other containers. One of the most obvious advantages of these machines is that they are safe for use. The filling and sealing process is all done in the machine, with no need for any manual intervention.

Ampoules are a type of sealed container for liquid medicine, vaccine or other product that is stored in small vials with a thin glass wall. Ampoules are used instead of vials because they are more efficient for storage purposes. They also provide increased visibility of the contents inside which helps when reading labels on vial labels.

If you looking for Ampoule Filling and Sealing Machine manufacturers in Ahmedabad, Machpack Process Machines offers the best Ampoule Filling and Sealing Machine.

Features of Automatic Ampoule Filling and Sealing Machine:

- Heavy duty base with robust construction off S.S. matt finished body

- Ampoule Filling & Sealing machine is specially designed for ampoule drawing, filling and sealing combined equipment for injections

- In this machine, belts / reciprocating agitators are provided in the feeding station. The filled ampoules in the sealing station are spun by rotating pinions of cylindrical rollers on the endless chain drive in cooperation with inclined discs.

- The machines are designed for operation in a sterile area and for use under laminar flow protection

- Ampoules will have complete grip throughout the process for proper fill and no spillage

- No ampoule No fill arrangement

- Easy and accurate adjustments of fill desired quantity with the help of change parts

- Various models available as per output speed requirement (1 / 2/ 4 head)

- Suitable for Pharmaceuticals filling and sealing

We also offer Airjet Cum Waterjet Bottle Cleaning Machine. To know more click here.

You must be logged in to post a review.

Technical Details

| Number Of Filling Head | 1 |

| Number of Inner Head | NA |

| Number of Sealing Head | 1 |

| Number of Applicator | NA |

| Production / Rate | 30 To 35 Tubes /Min (Depend On Fill Size And Material Characteristics and Efficiency of Operator) |

| Fill Size | 5 ml to 1000 ml (with the help of change parts) |

| Type of Product | Plastic, Leminated, Aluminium Tubes |

| Type of Filling Material | Cream, Paste, Semi Solid |

| Type of Seal | NA |

| Type of Label | NA |

| Label Specification | NA |

| Material Contact Part | SS 316 |

| Material Non-Contact Part | SS 304, SS Cladded MS Body Plate |

| Type of Technology | Syringe based, Pneumatic/ Mechanical System, Controller Based |

Reviews

There are no reviews yet.